ICHIBAN has implemented a number of Japanese technology and following a number of Japanese standard working procedure to harness the perfection from their technology. Kaizen and 5S are two main system that ICHIBAN is following as a religion spirit.

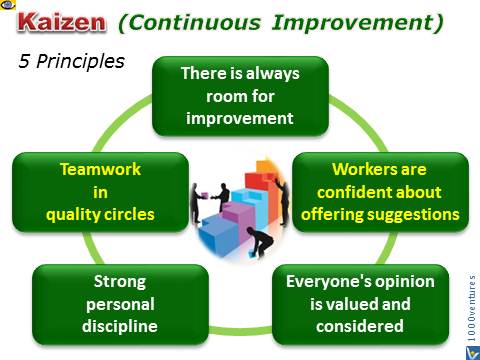

From the Japanese words “kai-” which means “change” and “-zen” which means “good” ; that’s how the concept of KAIZEN system evolved. It is also known as continuous improvement, is a long-term approach to work that systematically seeks to achieve small, incremental changes in processes in order to improve efficiency and quality. It means all personnel are expected to stop their work when they encounter any abnormality and, along with their supervisor, suggest an improvement to resolve the abnormality. ICHIBAN following this system in its manufacturing process.

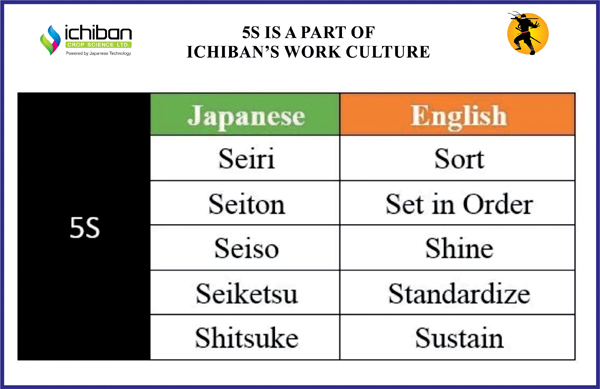

In other hand, 5S is another Japanese system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury

In Ichiban, we extensively use 5S along with other Japanese and international standards to make our system at par with international organisations.